Cross Hole & Hole Deburring for after drilling

Xebec brushes use unique abrasive ceramic fibre material instead of abrasive grains. The content ratio of ceramic fibres is an impressive 80% giving exceptional grinding power with a consistent cutting performance throughout the life of the brush. This is a real advantage compared to abrasive impregnated nylon brushes, where performance drops off over time, resulting in increased process times and mush higher frequency of brush replacement.

The Xebec products also maintain their shape for their full working life unlike other deburring materials that deform quickly; this improves the consistency of finish and eases management of them as a consumable on a mass production line.

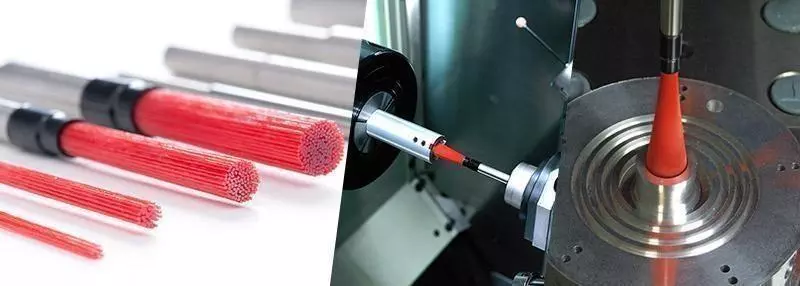

XEBEC Brush™ Crosshole

Ideal for deburring, polishing and cutter mark removal of inner diameter and counterbored part

Applicable Equipment

The tool can be mounted on an equipment which can control the rotational speed. The tool must be rotated over 8000min-1.

| Brush (Colour) | Product code | Brush diameter (mm) | Shaft diameter Dc(mm) | Shank diameter Ds(mm) | Bristle length (l) (mm) | Overall length L (mm) | Maximum rotational speed (min-1) | Target hole diameter (mm) | |||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A12(Red) | CH-A12-1.5M | 1.5 | 2.5 | 3 | 50 | 120 | 20000 | 3.5-5 | |||||||||||||||||||||||||||||

| CH-A12-3M-TL | 3 | 4 | 3 | 50 | 120 | 14000 | 5-8 | ||||||||||||||||||||||||||||||

| CH-A12-3L-TL | 3 | 4 | 4 | 50 | 170 | 12000 | 5-8 | ||||||||||||||||||||||||||||||

| CH-A12-5M-TL | 5 | 6 | 6 | 50 | 120 | 14000 | 8- 10 | ||||||||||||||||||||||||||||||

| CH-A12-5L-TL | 5 | 6 | 6 | 50 | 170 | 12000 | 8- 10 | ||||||||||||||||||||||||||||||

| CH-A12-7M-TL | 7 | 8 | 6 | 50 | 120 | 14000 | 10-20 | ||||||||||||||||||||||||||||||

| CH-A12-7L-TL | 7 | 8 | 8 | 50 | 170 | 12000 | 10-20 | ||||||||||||||||||||||||||||||

| CH-A12-11M | 11 | 12 | 12 | 50 | 120 | 14000 | 14-20 | ||||||||||||||||||||||||||||||

| CH-A12-11L | 11 | 12 | 12 | 50 | 170 | 12000 | 14-20 | ||||||||||||||||||||||||||||||

| A33(Blue) | CH-A33-3M | 3 | 4 | 3 | 60 | 130 | 14000 | 5-8 | |||||||||||||||||||||||||||||

| CH-A33-3L | 3 | 4 | 4 | 60 | 180 | 12000 | 5-8 | ||||||||||||||||||||||||||||||

| CH-A33-5M | 5 | 6 | 6 | 60 | 130 | 14000 | 8-10 | ||||||||||||||||||||||||||||||

| CH-A33-5L | 5 | 6 | 6 | 60 | 180 | 12000 | 8-10 | ||||||||||||||||||||||||||||||

| CH-A33-7M | 7 | 8 | 6 | 60 | 130 | 14000 | 10-14 | ||||||||||||||||||||||||||||||

| CH-A33-7L | 7 | 8 | 8 | 60 | 180 | 12000 | 10-14 | ||||||||||||||||||||||||||||||

| CH-A33-11M | 11 | 12 | 12 | 60 | 130 | 14000 | 14-20 | ||||||||||||||||||||||||||||||

| CH-A33-11L | 11 | 12 | 12 | 60 | 180 | 12000 | 14-20 | ||||||||||||||||||||||||||||||

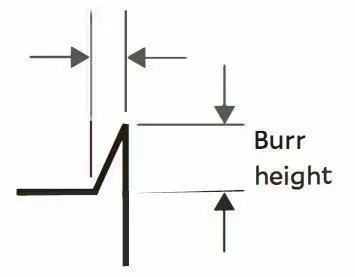

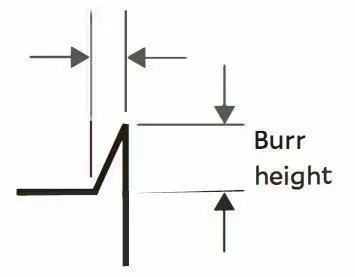

Target burr size

Burr root thickness of 0.1mm or less (Burrs are easily bent with a fingernail)

XEBEC Brush™ Crosshole Extra-Long Target burr size

Suitable for deburring, polishing and cutter mark removal of inner diameter and counterbored part exceeding 150mm in depth

Tool composition

Brush, collar and shank are separate items. (All special order items) Assemble brush to the shank with collar before use.

Applicable Equipment

The tool can be mounted on an equipment which can control the rotational speed. The tool must be rotated over 8000min-1.

| Brush (Colour) | Product code | Brush diameter (mm) | Shank diameter Ds (mm) | Overall length L (mm) | Maximum rotational speed (min-1) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A12 (Red) | * | 3 | 4 | 400 | 12000 | ||||||||

| * | 5 | 6 | 400 | 12000 | |||||||||

| * | 7 | 8 | 400 | 12000 | |||||||||

| * | 11 | 12 | 400 | 12000 | |||||||||

| A33 (Blue) | * | 3 | 4 | 410 | 12000 | ||||||||

| * | 5 | 6 | 410 | 12000 | |||||||||

| * | 7 | 8 | 410 | 12000 | |||||||||

| * | 11 | 12 | 410 | 12000 | |||||||||

* This is a special order item. Please contact us for the details.

Target burr size

Burr root thickness of 0.1mm or less (Burrs are easily bent with a fingernail)

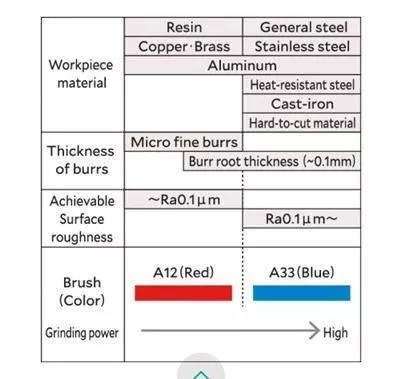

Which Brush do I need?

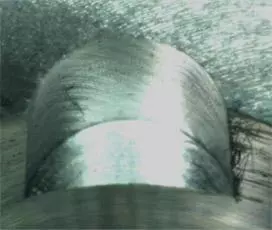

Case Study: Automotive / Deburring of hole edge

Tool Used: XEBEC CrossHole Deburring Tool Alumina Fiber Rod Type(CH-A12-5M)

RPM: 10,000min-1

Process Time: 2 sec/pc

Tool life: 1,600 pcs/tool

Before Crosshole Deburring of Edge

After Crosshole Deburring of Edge

Case Study: Automotive / Dead-end hole deburring

Tool Used: XEBEC Cross-Hole Deburring Tool CH-A12-3M(Ø3) + XEBEC Floating Holder

RPM: 2,000 min-1

Tool pressure: 3.0kgf

Process time:2 sec/pcs

Before Dead-end hole deburring

After Dead-end hole deburring

Hole Deburring Usage and Tips with the XEBEC Brush™ Crosshole

Refer to the chart and select Brush colour based on the workpiece material and burr root thickness.

- Insert the Brush while not in motion. * If you rotate the Brush outside the cylinder, the bristles may be damaged or scattered and may cause injury to an operator.

- Rotate the tool past the crosshole Consistent edge quality can be obtained by rotating the tool in both CW and CCW direction.

- Process while pulling the Brush back. Pulling the Brush back past the crossholes prevents burrs from being laid flat against the interior surface of the cylinder.

- Process while pushing the Brush forward.

- Stop the Brush rotation.

- Remove the Brush while it is at rest.

* XEBEC Brush has high grinding power on the tip. The Brush tip needs to be in contact with the processing area.

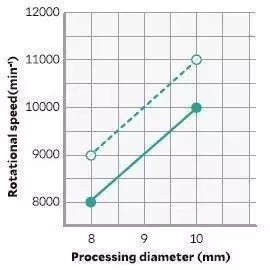

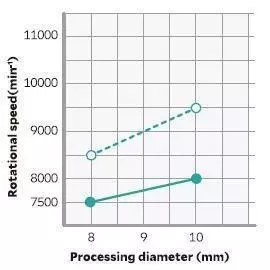

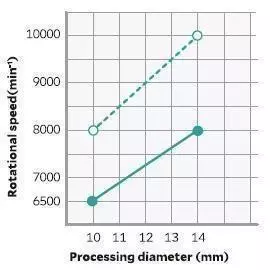

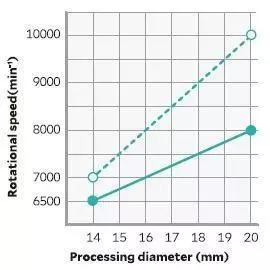

Processing conditions: Rotational speed

Recommended rotational speed is different depending on Brush diameter. See the diagrams below.

CH-A12-1.5M

Target hole dia.Ø3.5-5mm Recommended rotational speed: 9000-11000min-1

CH-A12-3M/3L

Target hole dia.Ø5-8mm Recommended rotational speed: 7000-10000min-1

CH-A12-5M/5L

Target hole dia.Ø8-10mm Recommended rotational speed: 8000-10000min-1

CH-A12-7M/7L

Target hole dia.Ø10-20mm Recommended rotational speed: 7000-9000min-1

CH-A12-11M/11L

Target hole dia.Ø14-20mm Recommended rotational speed: 6000-7500min-1

CH-A33-3M/3L

Target hole dia.Ø5-8mm Recommended rotational speed: 7500-9000min-1

CH-A33-5M/5L

Target hole dia.Ø8-10mm Recommended rotational speed: 7500-8000min-1

CH-A33-7M/7L

Target hole dia.Ø10-14mm Recommended rotational speed: 6500-8000min-1

CH-A33-11M/11L

Target hole dia.Ø14-20mm Recommended rotational speed: 6500-8000min-1

![]() Recommended rotational speed

Recommended rotational speed

![]() Rotational speed when the Brush is worn down 10mm

Rotational speed when the Brush is worn down 10mm

If burrs remain

- Increase rotational speed to the maximum in increments of 1000 min-1

- Increase the number of passes

If the workpiece cannot be deburred even by the above-mentioned procedures, the machining condition may be incorrect or the burr size is too large. Change the Brush with higher grinding power. The grinding power of the Brush : Blue> Red

To extend tool life, decrease the rotational speed in 10% increments or increase the feed rate in 10% increments

* Tool life significantly varies depending on processing conditions, burr conditions (size and direction) and workpiece material.

REFERENCE DATA: TOOL LIFE

Material: Carbon Steel S45C

Process details: Cross hole deburring after drilling process

Burr root thickness: 0.1mm

Hole diameter :

Main bore Ø10mm

Cross hole Ø5mm

Tool: CH-A12-SM

Rotational speed: 10000min-1

Feed rate: 300mm/min

Used length: 10mm out of 50mm

Tool life : 4500 holes