Hardness Testers and Testing

Machines designed for conducting hardness tests using various methods such as Brinell, Rockwell, Vickers, and Knoop, employing a wide range of loads.

The Significance of Hardness Testing

Hardness testing plays a crucial role in analyzing, distinguishing between different materials, developing and enhancing materials and technologies, and conducting fundamental research in the domains of materials science, materials engineering, and materials diagnostics. It helps determine essential values for assessing material usage in industries (evaluating suitability for relevant components), distinguishing materials (preventing material mix-ups), and investigating cases of damage (damage analysis).

How a Hardness Tester Functions

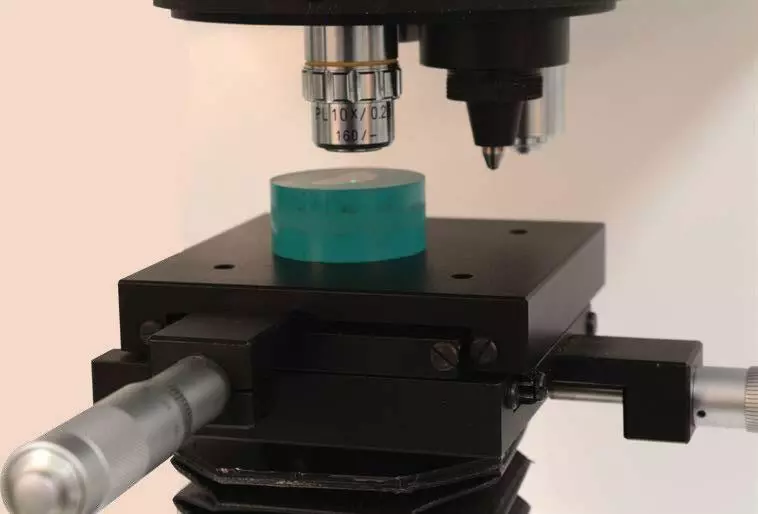

Hardness is a measure of a material's mechanical resistance against the penetration of a harder body (indenter). Diamond, as the hardest natural material, is commonly used as the indenter. Hardness testing primarily employs methods involving the static application of test forces, where the size or depth of the indentation caused by the indenter is measured. Static hardness testing methods can be categorized as depth measurement methods or optical measurement methods. Depth measurement methods gauge the residual depth of the indented area left by the indenter.

Is Hardness Testing Non-Destructive (NDT)?

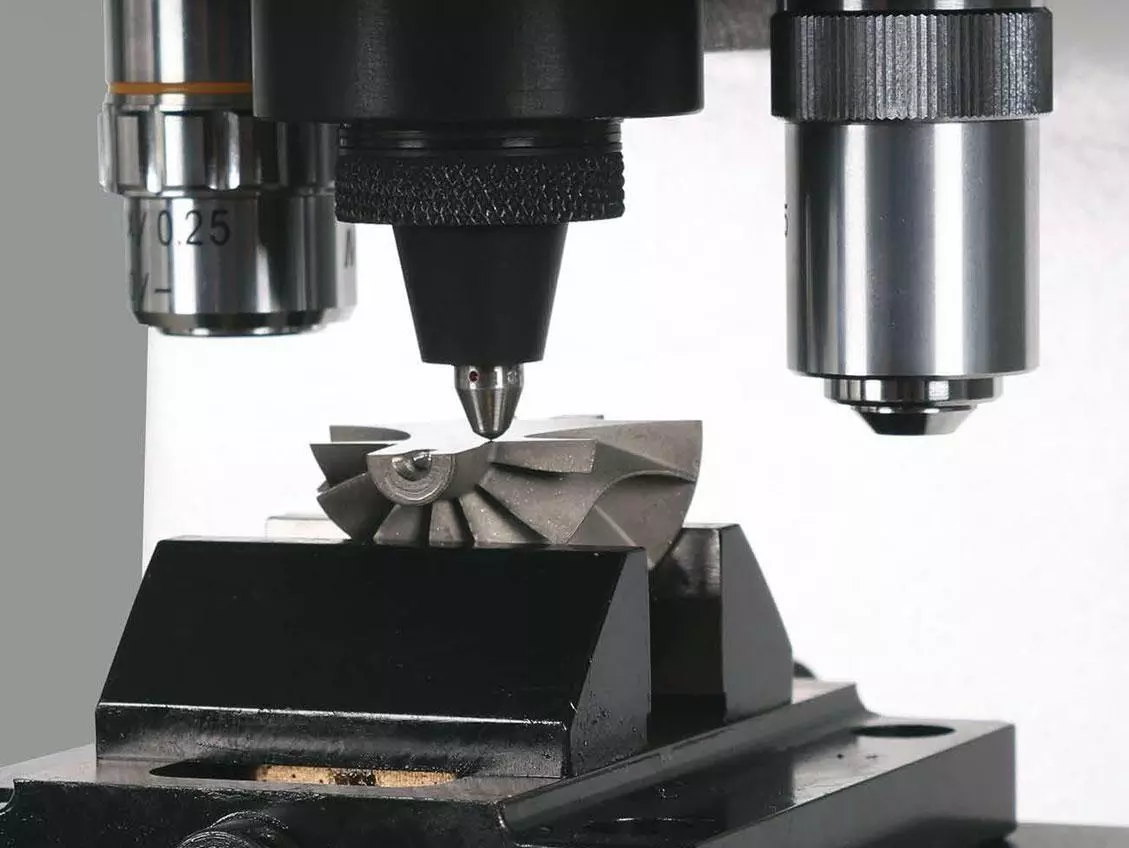

The non-destructive nature of hardness testing depends on the material and application being tested. When conducting hardness tests on raw materials like forgings or castings, which will undergo further processing to remove indentations, it can be classified as non-destructive testing (NDT). However, if the same hardness testing is performed on a critical aerospace turbine blade, it is considered destructive testing.

Hardness Testing vs. Impact Testing

Impact testing evaluates a material's ability to absorb energy when rapidly ruptured. It provides insight into the material's strength and typically employs two methods: Charpy or Izod.

In contrast, hardness testing assesses a metal or alloy's resistance to permanent indentation, with the size or depth of the indentation measured to determine its hardness value.

Hardness Testing and Its Types: Determining the Best Test

Rockwell

This method measures the residual depth of indentation made by the indenter. The softer the tested material, the deeper a specific indenter penetrates the surface of the specimen under a defined test force. The total test force is applied in two stages, eliminating the influence of surface roughness (specimen grooves) and measurement errors caused by indentation depth backlash.

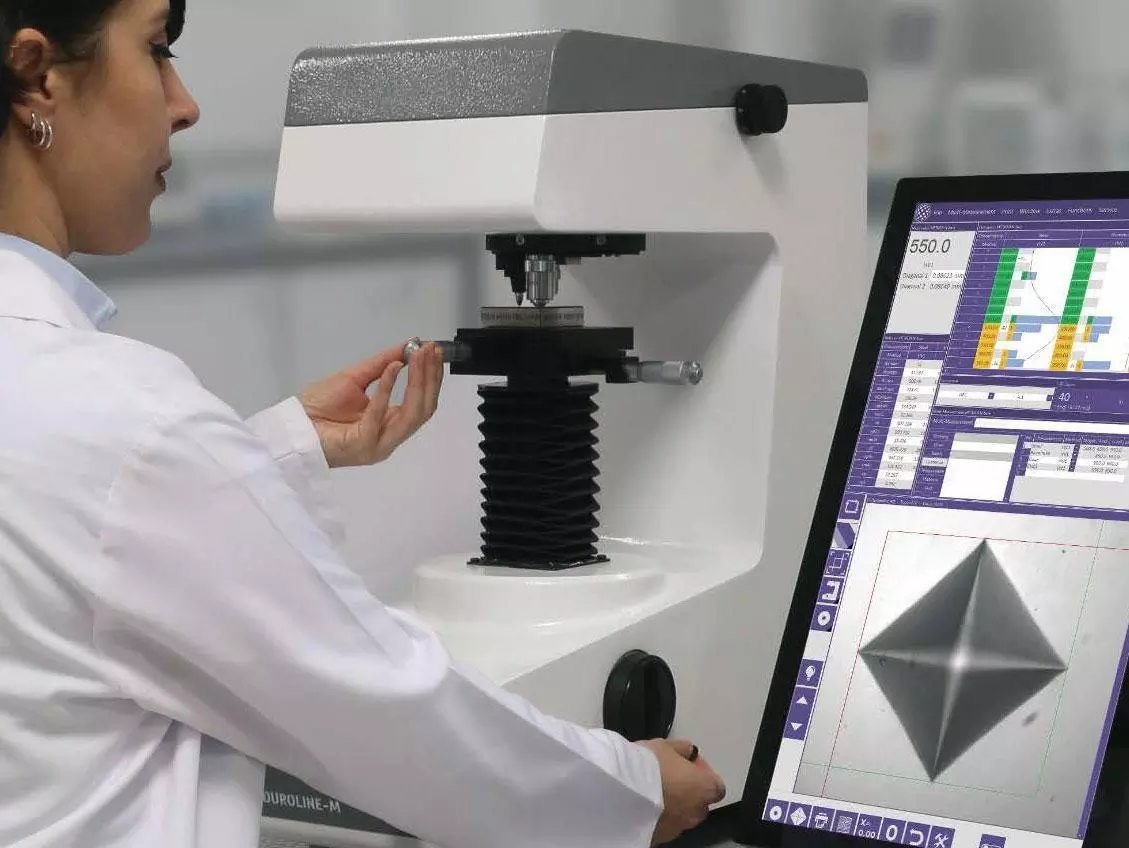

Vickers

An optical method that measures the size of indentation (diagonals) created by the indenter. In contrast to depth measurement methods (where only Rockwell is standardized), the Vickers method measures the depth of indentation caused by the indenter. The larger the indentation left by the indenter on the surface of a specimen under a defined test force, the softer the tested material. This method employs a pyramid-shaped indenter (with an interfacial angle of 136°) pressed into the specimen using a defined test load starting from 1 gf.

Brinell

This optical method involves pressing a spherical indenter into the specimen, with the size of indentation left by the indenter being measured. The larger the indentation left on the surface of a workpiece (specimen) by the Brinell indenter, with a specific ball diameter and test force, the softer the tested material. To determine the HBW (Brinell hardness value), the tungsten carbide indenter is pressed into the specimen with a defined test load ranging from 1 kgf to 3000 kgf. The HBW is obtained by dividing the applied test force (F in newtons (N)) by the surface area of the residual indentation on the specimen after removing the test force.

Knoop

An optical method that involves pressing a pyramid-shaped rhombic indenter (with a longitudinal edge angle of 172.5° and a transverse edge angle of 130°) into the specimen using a defined test load ranging from 1 gf to 2 kgf. The larger the indentation left by the indenter on the surface of a specimen under a defined test force, the softer the tested material.