Industrial Ultrasonic Cleaners - Injection Mould Ultrasonic Cleaner

The Corus units are intended for general maintenance cleaning applications. Tank dimensions are based on Euro pallet standard. Cleaned parts are to be placed into cleaning tank in a wash basket. Each unit is an independent module. Modules can be placed next to each other to form a line with washing, rinsing and drying stages. System can be further complemented with storage tanks, filtration, Ergo Station, chain hoist etc.

| Model | Wash basket internal dimensions | Load capacity | US effect | Tank volume | Heating effect |

|---|---|---|---|---|---|

| Corus 120 | 300 x 538 x h442 mm | 100 kg | 1.2 kW | 135 l | 3 kW |

| Corus 240 | 604 x 400 x h516 mm | 200 kg | 2.4 kW | 262 l | 5 kW |

| Corus 360 | 808 x 600 x h658 mm | 300 kg | 3.6 kW | 670 l | 9 kW |

| Corus 480 | 1208 x 800 x h658 mm | 350 kg | 4.8 kW | 1200 l | 18 kW |

Corus HD - Mould Ultrasonic Cleaner

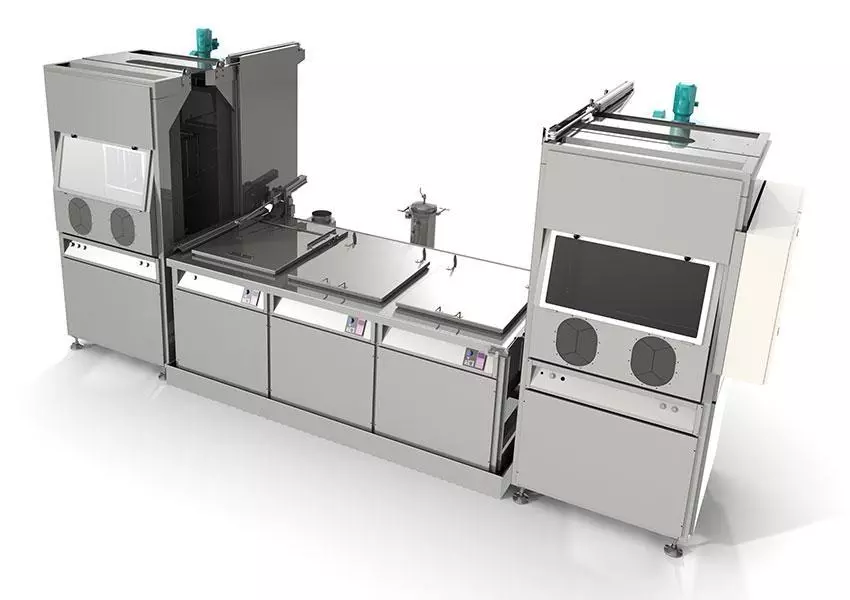

Corus HD units are intended for maintenance cleaning of e.g. tools and moulds. Each unit is an independent module. Modules can be placed next to each other to form a line with washing, rinsing and drying stages. Typical process consists of two steps/ tank modules: ultrasonic wash complemented with immersion rinsing/ hot passivation, but hot air dryers are available.

Tank dimensions are based on typical injection mould sizes. Cleaned parts are to be placed into tank either in a wash basket or hung on a lifting beam. Both baskets and lifting beams are compatible with the standard tank designs. System can be further complemented with storage tanks, filtration, Ergo Station, chain hoist etc.

Moulds are handled with lifting beams (optional) matching the dimensions and weight capacity of the cleaning machine. Operator lifts moulds to and from tanks with a hoist (not included). The wash tank is equipped with supports for the lifting beam bearing the mould. Chain hoist can be detached and lid closed for the duration of the cleaning. In rinse and passivation stages, which are typically a matter of minutes, the lifting beam is supported with the hoist during treatment. Control devices like temperature and treatment time controller and start/stop push button are located on a panel at the front of the tanks.

| Model | Max recommended mould size | Load capacity | Tank effective dimensions | Basket internal dimensions | US effect | Tank volume | Heating effect |

|---|---|---|---|---|---|---|---|

| Corus 120HD | 400 x 250 x 400(h) mm | 100 kg | 340 x 645 x 484(h) mm | 300 x 538 x 435(h) mm | 1.2 kW | 135 l | 3 kW |

| Corus 240HD | 450 x 300 x 450(h) mm | 200 kg | 654 x 449 x 603(h) mm | 604 x 400 x h516 mm | 2.4 kW | 286 l | 5 kW |

| Corus 360HD | 600 x 400 x 600(h) mm | 300 kg | 724 x 473 x 758(h) mm | 668 x 400 x h658 mm | 3.6 kW | 410 l | 9 kW |

| Corus 480HD | 800 x 400 x 600(h) mm | 500 kg | 924 x 473 x 758(h) mm | 868 x 400 x h658 mm | 4.8 kW | 500 l | 9 kW |

Options

- Baskets, single lifting point with gripper

- Lifting beams, same support points as for basket

- Rim lip ventilation channel and fan

- Lift off, hinged and pneumatic operated lids

- Closed loop circulations

- Storage tanks VG50, VG140,

- VG140HD with vertical pump

- Noise suppression kit 85 > 71dB

- Chain hoists

Construction

- Modular: each module is an independent unit

- Modern and cost effective sheet metal construction

- Valves at the back

- Adjustable feet

- Raised lip at tank edge

Loading concept

- Basket supports at tank edge

- Manual / hoist basket

- Lifting beam

Main applications

- Tool and mould cleaning

- Plastic injection moulds

- Die casting

- Rubber moulds

- Glass packing moulds

- Extrusion tools

- General maintenance cleaning

- Coolers

- Filters

- Manufacturing equipment

- Engine parts

Corus Activa - For Heavy Duty and Industrial Maintenance

Streamlined and cost-efficient maintenance process of complex parts

- Short cleaning process

- Superior cleaning results with ultrasonic cleaning

- Reduced manual labour

- Water-based and an energy-efficient process

Safe and easy operation

- The load platform makes the part handling easy

- An insulated lid keeps the heat in the tank

- Pneumatic actuation (optional) of the lid makes the operation safe and comfortable

Easy and efficient operation

Parts are loaded with the platform in the upper position. Platform is lowered with two-hand safety controls. Lid is closed manually. Treatment is started by pressing the start button. After treatment the lid is opened manually, and the platform is raised with two-hand safety control for the unloading of parts.

- Truly robust and safe load handling with double guides and cylinders on the load platform lifting system.

- Safety and comfort of the operation is improved with the pneumatic actuation of the lid (on Corus Activa 480 only).

- Insulated lid with gas springs – keeps heat in the tank with added safety for the operator.

- Dunking movement of the platform contributes to fast and uniform washing.

- Constant maximum performance and high level of cleanliness thanks to the state of the art ultrasonic technology with automatic frequency and power regulation.

- Ultrasonic transducers on two sides (front and back) – Full coverage of load area without dampening due to sludge accumulation over transducers.

- Heating – multiplies detergent cleaning power.

| Corus Activa 240 | Corus Activa 360 | Corus Activa 480 | |

|---|---|---|---|

| Load platform dimensions and usable height | 800 x 500 x h400 mm | 1100 x 600 x h400 mm | 1250 x 700 x h650 mm |

| Load capacity | 250 kg | 250 kg | 500 kg |

| Tank capacity | 309 l | 498 l | 898 l |

| Ultrasonic effect (nominal) | 2.4 kW | 3.6 kW | 4.8 kW |

| Heating effect | 12 kW | 15 kW | 30 kW |

Options

- Pneumatic actuation of the lid (Corus Activa 240 and 360) - adds to the safety and comfort of the operation

- Rim lip ventilation with extraction fan – reduces exposure to vapors and heat

- Closed loop circulation with P1S or P2S bag filter – increases bath life and improves cleanliness result

- Extended storage weir with circulation pump – enables skimming of oil from tank surface avoiding recontamination of parts when lifting out

- Rinsing units with air bubble agitation also available

Mi Range - Industrial Ultrasonic Cleaners

Explore the flexible and affordable ultrasonic cleaners for maintenance and production. Manage the parts cleaning process with the easy to use control system.

Modular floor standing ultrasonic cleaners are engineered for optimum cleaning result. The stainless steel ultrasonic cleaning tanks are used as single-stage bench top units or as part of a fully integrated modular cleaning system.

Control unit features- Digital control panel FIN13 “V03”

- Adjustable treatment time (00:00 – 500:59 mmm:ss) and temperature with three programmable presets

- Temperature limit

- 7-day timer

- External control

- Temperature interlock

- Dry run protection

As well as cleaners, our range includes rinsers, hot air dryers, dewatering tanks, filtration, oil separators, platforms and automation.