KemCut - Abrasive Cutting & Precision Cutting Machine

The KemCut is the ideal solution for preparing metallographic samples, offering versatile and high-quality cutting capabilities for laboratories, research facilities, and industrial applications. Whether you're conducting material analysis, quality control testing, or research and development work, the KemCut delivers consistent, precise results that meet the demanding requirements of modern metallography.

This professional-grade machine is specifically designed for wet cutting of both large and small workpieces, whether regularly or irregularly shaped, across a wide range of materials including metallic, ceramic, and composite materials. The wet cutting process ensures that samples remain cool during sectioning, preventing thermal damage, material distortion, or microstructural changes that could compromise your analysis results.

The KemCut's versatility makes it suitable for cutting everything from delicate electronic components and small precision parts to larger industrial samples and forgings. Its robust design accommodates specimens of varying geometries, including cylindrical, rectangular, and irregular shapes, making it an indispensable tool for any materials testing laboratory or quality assurance department.

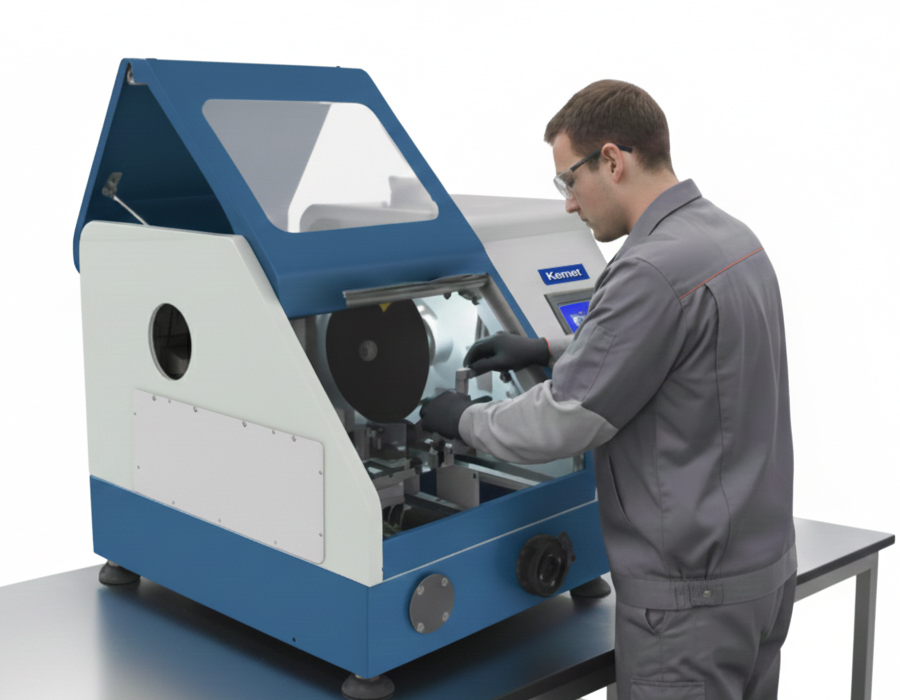

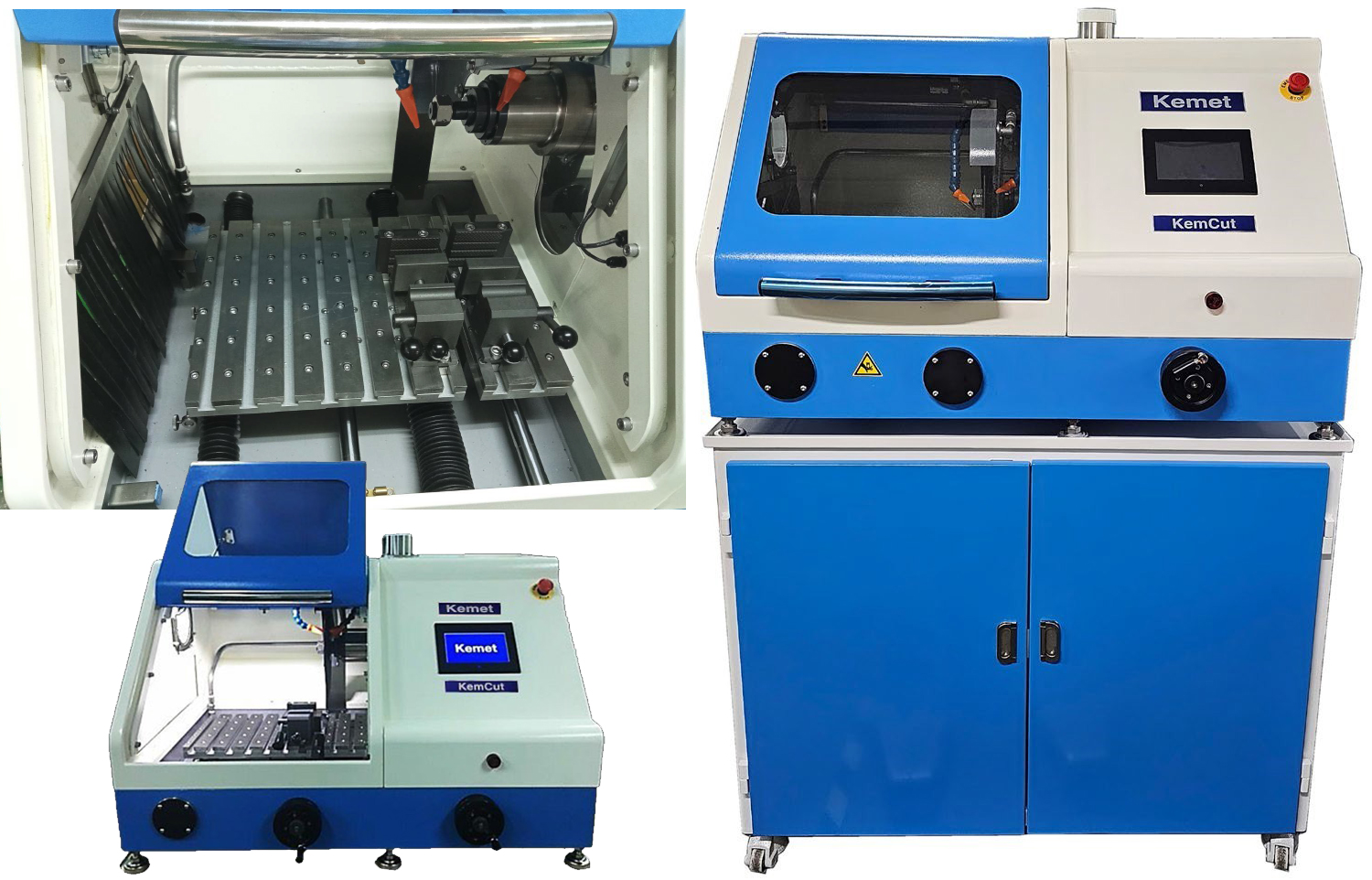

Equipped with a powerful motor driving the cut-off wheel, the machine is built on a robust casting base with a precision cutting table that ensures stability and accuracy throughout the cutting process. The complete system is enclosed in a protective hood with a shatter-proof window, and the cutting chamber is illuminated with internal lighting to enable safe observation of the cutting process at all times. This combination of power, precision, and safety makes the KemCut the preferred choice for professionals who demand excellence in sample preparation.

Key Features and Benefits

Powerful Performance

Equipped with a robust 5 HP (4kW) cutting motor with variable wheel speeds from 600 to 3500 rpm, ensuring optimal cutting performance for different materials and applications.

Safety Design

Complete system enclosed in a protective hood with shatter-proof window and illuminated cutting chamber for safe observation of the cutting process at all times.

Robust Construction

Built on a robust casting base with a precision cutting table, providing stability and accuracy for consistent results in sample preparation.

Versatile Clamping

Multiple special stainless steel clamping devices attach to the T-slot bed in seconds, enabling fast and positive clamping in virtually any configuration for irregularly shaped samples.

Technical Specifications

| Specification | Details |

|---|---|

| Maximum Wheel Diameter | 250mm / 305mm |

| Maximum Cutting Capacity | 60mm (Ø250mm wheel) / 90mm (Ø305mm wheel) |

| Maximum Cutting Capacity (H×D) | 60 × 130mm / 90 × 115mm |

| X-Axis Travel | 65mm / Motorised |

| Y-Axis Travel | 210mm / Motorised |

| Z-Axis Travel | 100mm / Manual |

| Y-Axis Table Feed Speed | 0.01 – 12 mm/sec (Variable) |

| Table Dimension | (360 + 65) × 260mm |

| T-Slot Dimension | 12mm |

| Cutting Chamber Height | 468mm |

| Chop Cutting (Z-Axis) | Manual |

| Table Feed Cutting (Y-Axis) | Automatic |

| Cutting Motor Power | 5 HP (4kW) |

| Wheel Speed Range | 600 ~ 3500 rpm (Variable) |

| Pump Power | 1/8 HP |

| Cooling Tank Capacity | 80 Litres |

| Control Panel | HMI (Human Machine Interface) |

| Dimensions (W × D × H) | 974 × 956 × 1486mm |

| Hood Open Height | 974 × 956 × 1720mm |

| Weight | Approximately 370kg |

| Electric Supply | 380V / 415V 3Phase 50/60 Hz |

Applications and Sample Preparation

The KemCut abrasive cutting machine excels in numerous sample preparation applications where precision and quality are paramount:

- Metallographic Analysis: Perfect for sectioning specimens for microscopic examination and material analysis

- Quality Control: Ideal for preparing samples from production components for inspection and testing

- Research & Development: Essential tool for materials research laboratories requiring precise sample preparation

- Failure Analysis: Enables accurate sectioning of failed components for root cause investigation

- Multi-Material Cutting: Handles metallic, ceramic, and composite materials with ease

Specialized Clamping Solutions

Many sample preparation applications require sectioning specimens from small or irregularly shaped samples or component parts, which can create positioning and clamping difficulties. To overcome these challenges, the KemCut system includes several special clamping devices:

- All clamping devices manufactured from stainless steel for durability and corrosion resistance

- Quick attachment to T-slot bed in seconds for rapid setup

- Enables fast and positive clamping in virtually any configuration

- Accommodates irregular geometries and challenging workpiece shapes

- Multiple clamping options for maximum versatility

Advanced Control System

The KemCut features an intuitive HMI (Human Machine Interface) control panel, providing:

- Easy operation and monitoring of cutting parameters

- Variable wheel speed control (600-3500 rpm) for material-specific optimization

- Adjustable table feed speed (0.01-12 mm/sec) for precise control

- Motorized X and Y-axis travel for automated cutting operations

- User-friendly interface for efficient workflow